Recent Posts

Get in touch!

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

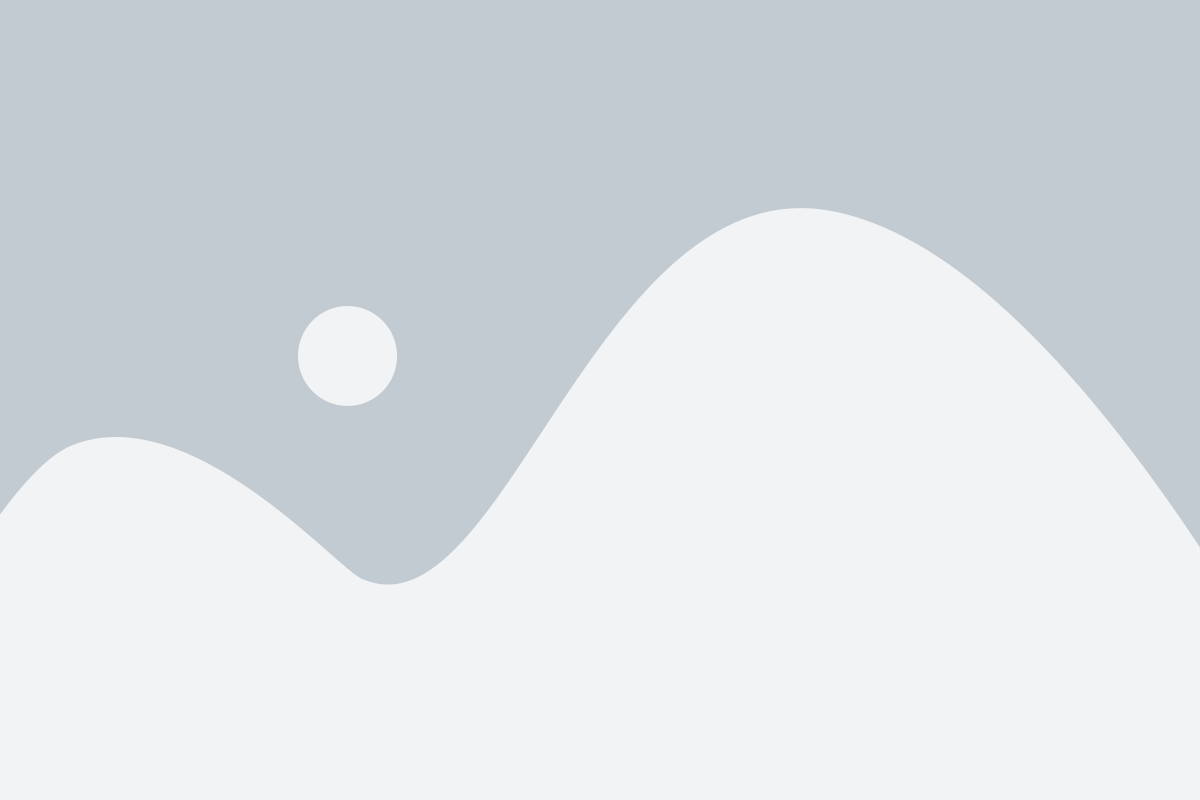

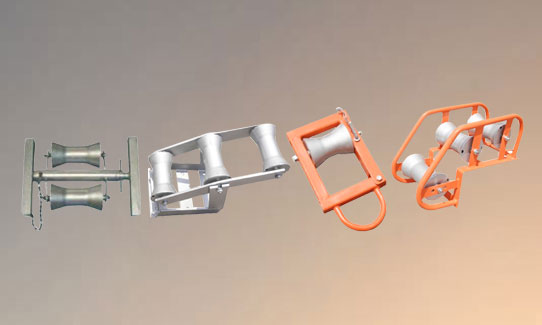

Trench Cable Rollers are specifically used for straight pulling applications, where cables are fed through trenches without bends or sharp turns. There are different types of trench cable rollers for different straight pulling applications. In this category, we offer basic, heavy duty, long base and narrow rollers. Each one is differentiated from one another based on the diameter of the cable. The Frames are either Powder Coated or Galvanised while the Rollers are Hot Dip Galvanised in accordance with BS-729 and the finish is fabricated with Black Steel.

For low-weight and low-tension cables.

For handling thick, heavy cables.

For laying in long-ranged trenches.

For laying in short-ranged trenches or tight spaces.

| Specifications | Normal Straight | Heavy duty | Long base | Narrow base |

|---|---|---|---|---|

| Length (mm) | 300 | 400 | 580 | 320 |

| Width (mm) | 210 | 240 | 220 | 145 |

| Height (mm) | 260 | 205 | 190 | 165 |

| Weight (kg) | 5.5 | 6.5 | 6.0 | 2.75 |

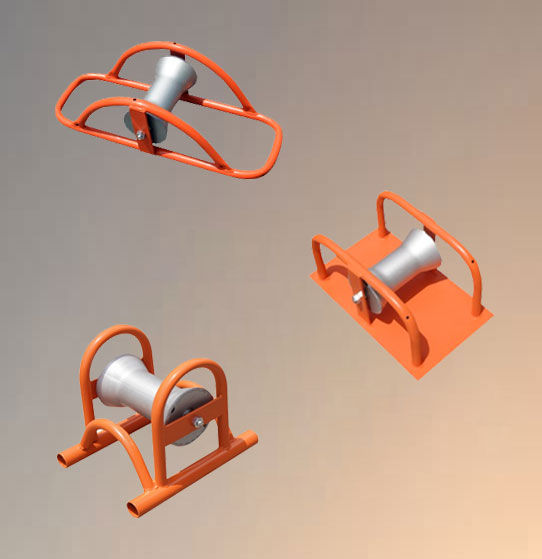

Guiding cables around corners and bends in trenches during underground cable laying operations need specific trench roller cable. We provide trench cable rollers for corner applications. They help to protect the cables from damage caused by friction and sharp bends that can occur when pulling them through the trench. The key feature of Corner Rollers is that they can be linked together with stake pins or can be used individually as well. Thus it offers improved cable guidance and flexibility while configuring your corner roller setup.

The Triple Corner Roller (Type 1 & Type 2) and the Double Corner Angled Roller are used for pulling Cable around sharp corners, whereas the Bend/Vertical Horizontal is more suitable to take the cables around a bend rather than around a corner.

The Triple Corner Roller consists of two vertical and one horizontal pulley made of precision steel tube and are hot dip galvanized in accordance with BS-729. The frame is either Powder Coated or Galvanised. The Double Corner Roller consists of one vertical and one horizontal pulley made of Precision Steel Tube. Meanwhile, the Bend Roller consists of 12 Vertical and 5 Horizontal Pulleys made of Precision Steel Tube and the frame is either Galvanised or Powder Coated. Please note that Bend Rollers can also be provided as with 6 Vertical X 3 Horizontal Rollers.

| Specifications | Triple Corner Roller (Type - 1) | Triple Corner Roller (Type - 2) | Double Corner Angled Roller | Bend/Vertical Horizontal Roller |

|---|---|---|---|---|

| Length (mm) | 400 | 400 | 280 | 1590 |

| Width (mm) | 340 | 340 | 160 | 345 |

| Height (mm) | 345 | 345 | 300 | 300 |

| Weight (kg) | 14 kg | 14 kg | 9.5 kg | 52 kg |

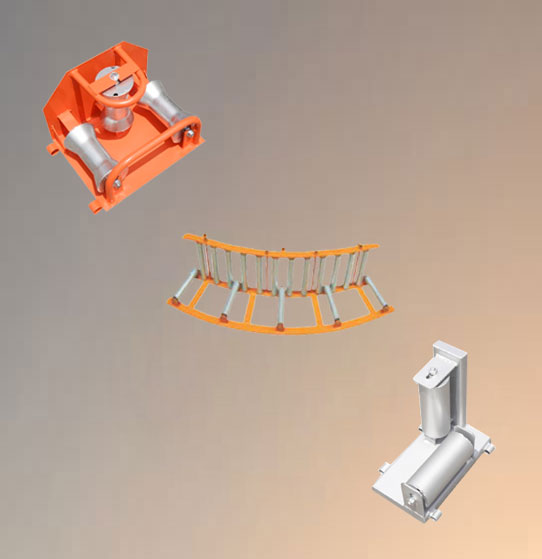

Draw off roller, Cable guide & support roller (heavy duty), Cable guide and support roller (Light duty), Draw off Roller With Stand/Step Roller

Cable guide rollers are primarily used for pulling and laying the cables in trenches which vary in depths, without the usage of normal rollers. We offer Cable Guide Rollers for different applications. Normal Draw off Rollers, Light Duty Draw Off Roller With Stand/Step Roller, Cable Guide & Support Roller, and Draw off Roller With Stand/Step Roller.

The Draw Off Roller mainly comprises a Steel Tube Roller placed on a Heavy Duty Angle Steel Base for maximum stability when pulling. Besides, a STEP ROLLER or STAND will be attached along with the Roller in order to increase the height and thereby the cables are placed at the most accurate position. The height of the STEP ROLLER is customized according to the client’s requirement.

The Cable guide and Support Rollers, mainly consist of two guiding and supporting rollers which are placed in a ‘V-SHAPE’. The Pulley body is made of High Precision Steel Tube. The customer also gets the option to choose between Light Duty and Heavy Duty Guide Rollers. The Rollers are usually placed right in front of the cable drum, so that the cable can be centralized and it can be placed into the trench with accuracy.

| Specifications | Draw Off Roller | Cable Guide Roller (Heavy duty) | Cable guide & support roller (light duty) | Draw off Roller With Stand/Step Roller |

|---|---|---|---|---|

| Length (mm) | 1060 | 1000 | 1000 | 1050 |

| Width (mm) | 180 | 500 | 500 | 1800 |

| Height (mm) | 220 | 500 | 500 | 0.25 - 3 |

| Weight (kg) | 15 | 35 | 20 | 50 - 135 |

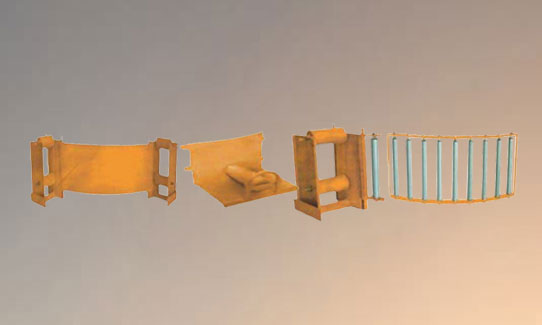

Bend rollers are fundamentally applied in complicated cable laying operations such as cables needing to navigate complex pathways with multiple bends and curves. The rollers ensure smooth cable installation by reducing friction.

We offer three types of bend rollers: vertical roller, horizontal roller, and skid roller. We also provide skid plate with horizontal roller.

The Vertical Roller consists of nine vertical Steel Rollers mounted on a heavy duty frame. If the size of the pulling cable is more than 130mm, the vertical roller can be combined with the horizontal roller.

The horizontal roller consists of two rollers; one is placed horizontally and other vertically outside on the frame. The Frame for both rollers is available with Powder Coated or Galvanized finish.

The Skid Plate with Horizontal Roller consists of four rollers placed horizontally on a steel base frame which is bent in order to pull around bends.

The Skid Roller consists of only one roller placed on a steel base frame which is also bent similarly like the Skid Plate with Horizontal Roller. However, the Skid Roller contains stake pins so that multiple rollers can be combined together.

| Specifications | Vertical Roller | Horizontal Roller | Skid Plate With Horizontal Roller | Skid Roller |

|---|---|---|---|---|

| Length (mm) | 900 | 250 | 1400 | 230 |

| Width (mm) | 150 | 260 | 260 | 230 |

| Height (mm) | 310 | 400 | 400 | 300 |

| Weight (kg) | 15 | 13.5 | 34 | 8.5 |

Suspension Rollers and cable protection cables are usually used in places where the cables have to be placed from the floors onto overheads or on cable trunks. The Suspension Rollers come for both Heavy Duty and Light Duty applications to meet the client’s unique requirements.

The Heavy Duty is ideal for taking the initial strain on much heavier cables when they are lifted from the floor and taken onto the cable trunkings. On the other hand, the Light Duty focuses on less heavier cables while applicable for the same operation. Both the rollers are hung from a cross beam for overhead laying. The Rollers frames are either powder Coated or Galvanized as per customer’s request, while the rollers are made of High Precision Steel Tube.

The Cable Protection Rollers are made of Precision Steel Tube running on a heavy duty sealing ball. It also contains an adjustable spindle with tetragonal thread and is available with single or double rollers.

The Manhole Triple Roller, unlike the Suspension Roller, is usually placed at either the pit or manhole’s entrance or at the end. The Rollers are mainly used to help lay cables on overhead cable trays. It mainly consists of three rollers made of Precision Steel Tube. The frame can either be Powder Coated or Galvanized.

| Specifications | Suspension Roller -Heavy Duty | Suspension Roller - Light Duty | Protection Roller | Manhole Triple Roller |

|---|---|---|---|---|

| Length (mm) | 250 | 900 | 310 | 500 |

| Width (mm) | 120 | 150 | 410 | 250 |

| Height (mm) | 440 | 310 | 120 | 630 |

| Weight (kg) | 10 | 3 | 10 | 15 |

The Duct Cable Rollers are usually used where cable pulling applications are done in ducts. Duct Cable Rollers mainly consist of two types of equipment: Bell Mouth without Roller and Bell Mouth with Roller.

Both these rollers serve the same purpose of ensuring maximum safety to both the cables and the ducts whilst pulling along ducts. The Bell Mouths are placed at the ducts entrance or end of the ducts. Customers may choose either one of the Bell Mouths depending upon their requirement and the size of the duct. The Bell Mouths can also be made in different sizes or dimensions as per customer request. The Bell Mouth with Rollers can be provided in two types as illustrated below. The Rollers are placed above the Bell Mouths to make sure that the pulling of the cables is more easy and smooth in the ducts. Sizes can be made right from 76mm up to 210mm.

The Guide Rollers are generally used at the entrance of the manhole in order to reduce the damage which is caused on the ropes or cables while pulling without the usage of rollers. The Guide Rollers mainly consist of Rollers which are either made of cast iron or made of Nylon. They are placed on a Hot Dip Galvanized Frame.

Winches, the most essential equipment for cable installation and pulling, is one of Elfit Arabia’s flagship products. Our winches come with enhanced features and unique technology to bring maximum efficiency and ease of use in cable laying works.

View Details

Elfit Arabia’s cable drum trailers are perfect for large innerduct reels, cable reels, strand reels, fiber reels, wire ropes reels and more. With our trailers, it is easier than ever to guide or reel the cables from the drums for underground laying purposes.

View Details

Trench Cable Rollers are specifically used for straight pulling applications, where cables are fed through trenches without bends or sharp turns. There are different types of trench cable rollers for different straight pulling applications.

View Details

Cable Drum Lift Jacks are primarily used for lifting cable drums. At Elfit Arabia, we offer a wide range of jacks to meet the myriad applications and requirements in lifting various kinds of cable drums. As an approach towards working with ease,

View Details

The Cable Locator is used to determine the exact location of buried cables prior to any form of excavation work taking place.Measuring Wheels are used to measure distance along routes in the cable network.

View Details

The Duct Cable Rollers are usually used where cable pulling applications are done in ducts. Duct Cable Rollers mainly consist of two types of equipment: Bell Mouth without Roller and Bell Mouth with Roller.

View Details

Pulling grips help in installing or repairing cables or wires in overhead and underground applications. They are easy and fast to install, providing the user with a smooth, slim profile that allows for easy passage through ducts.

View Details