Recent Posts

Get in touch!

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

Fusce varius, dolor tempor interdum tristiquei bibendum service life.

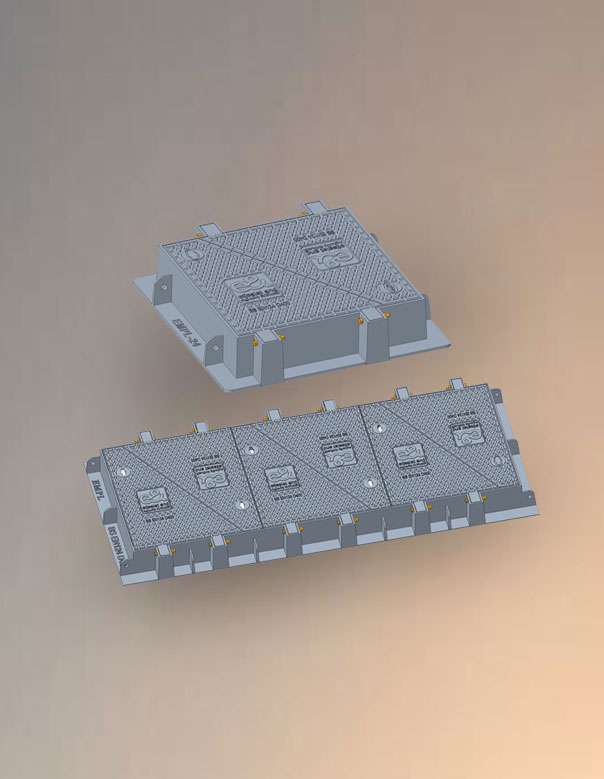

Elfit Access Covers and Frames deliver exceptional durability, strength, and consistent quality. Engineered using advanced software and rigorous testing, they are optimized for minimal weight while exceeding the design breaking load of 480 kN for Class D400 covers. Current production consistently surpasses this standard, with covers breaking between 470-510 kN. Manufacturing adheres to BS EN 124, including routine load testing.

| Manhole Standard Etisalat (e&) | Manhole Standard DU |

|---|---|

| CW1 (CLASS D 400) | CW2 (CLASS D 400) |

| CW2 (CLASS D 400) | CW3 (CLASS D 400) |

| CW3 (CLASS D 400) | CW4 (CLASS B 125, 150 KN TEST LOAD) |

| CW4 (CLASS B 125, 150 KN TEST LOAD) |

| Type | Clear Opening (MM) | EN124 CLASS |

|---|---|---|

| Carriageway 1 | 600 X 600 | D 400 |

| Carriageway 2 | 1224 X 700 | D 400 |

| Carriageway 3 | 1835 X 700 | D 400 |

| Carriageway 4 | 912 X 452 | B 125 |

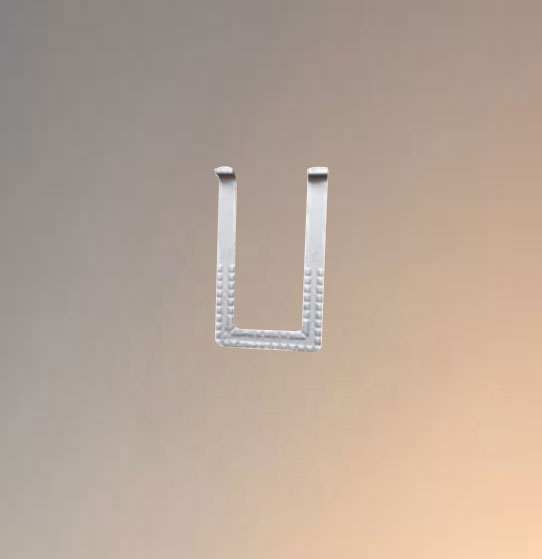

The design for Manhole Step No. 1, shown in the data sheets was arrived at through minute consideration of safety, durability and other factors. An additional rib has been added to increase the strength of the ruling section and to reduce susceptibility to failure through crevice corrosion. Material specified is Ductile Iron Grade 420-12 rather than Malleable Iron Grade B35-12. Ductile Iron is a superior material to Malleable Iron and has largely replaced it. Unlike Ductile Iron, Malleable Iron components must be heat treated after casting to obtain the desired properties, which increases the production costs over that for Ductile Iron.

A load of 6 kN, applied at the Centre of the step with the legs clamped, in the manner prescribed in British Standard BS1247 Part 1, is specified for routine testing of production units.

A generous tread pattern, 3 mm high, is provided for positive grip. Step corners have been rounded, generously, to reduce the potential for impact injuries.

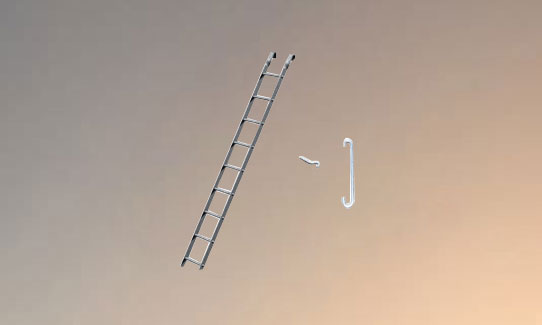

Material: Mild Steel Protective Finish: Hot dipped galvanised in accordance with BS729 Design specification: Ladders, Hooks and Bar comply with Etisalat specification MS109. Standard Lengths: 2150, 2300, 2450, 2600, 2750, 3000, 3250, 3500, 3750.

Material: Bearers: Mild Steel Pressed Channel Bolts: Mild Steel Pins: High Tensile Steel Rod Protective Finish: All items - Hot dipped galvanised in accordance with BS 729. Design specification: Bearers: MS 105 Bolts: MS 108 Pins: MS 101 Standard Lengths Bearers: 178, 279, 508, 813, 1270, 1574 & 1879 Bolts: 127 (1/2 in. Dia) and 150 (5/8 in. Dia)

Material: Mild Steel Bar, normalised at 650 degree C after forming. Protective Finish: Hot dipped galvanised in accordance with BS729 Design specification: Etisalat Specification MS 103

We manufacture and sell all types of cable laying products ranging from winches to trailers to rollers to cable locators and many more. Our cable laying products are manufactured with high precision using premium materials. The customized products and equipment are available in multiple specifications to meet normal and complex operations. Checkout our wide range of products.

Read More

Elfit Access Covers and Frames deliver exceptional durability, strength, and consistent quality. Engineered using advanced software and rigorous testing, they are optimized for minimal weight while exceeding the design breaking load of 480 kN for Class D400 covers. Current production consistently surpasses this standard, with covers breaking between 470-510 kN. Manufacturing adheres to BS EN 124, including routine load testing.

Read More

At Elfit Arabia, we specialize in offering a diverse range of premium rope products suited for various industrial, commercial, and general-purpose applications. Our rope products are engineered to deliver durability, strength, and superior performance. We promise that our rope products meet highest quality standards and efficiency needed for a wide range of applications.

Read More

Elfit Arabia is a platform that offers a wide range of telecom products. From essential cables and connectors to distribution boxes and earthing equipment, we offer telecom products in 15 categories. Our products cover everything related to telecommunication operations such as build, maintain, and optimize the telecom infrastructure. Our products can be customized to meet your unique needs.

Read More

Elfit Arabia offers a wide range of Fiber Optic Products designed to meet the needs in diverse industries including telecom, networking, military, IT infrastructure and so on. We offer customized products to suit the demands and needs of our customers to ensure maximum efficiency of our solutions. Our fiber optic cables are known for their excellent performance in terms of bandwidth and signal attenuation.

Read More

At Elfit Arabia, we offer a wide range of premium quality electrical OSP solutions. Here you will get all solutions to build a secure, organized, and efficient electrical system for your outside plant (OSP) applications.Our extensive category of products includes essential cable management solutions like cable ladders and trays, channels and fittings, and channel straps. You'll also find a variety of cable clamps and saddles for secure and organized cable routing. We also offer Gland Accessories and Earthing products and accessories.

Read More

Elfit Arabia offers a diverse collection of solar products which are cost effective, environment friendly and help in reducing dependency on non-renewable resources. Our list of products are designed to harness the power of the sun for various applications. All of our products are built to withstand weather conditions and stay longer for several years with minimal maintenance. They are also secure and safe for multiple applications.

Read More